Mirror stainless steel undergoes a series of polishing processes that enhance its surface smoothness and reflectivity. The “K” in the mirror grade (for example, 4K, 6K, etc.) refers to a degree of polish, with higher numbers indicating a finer and more polished surface.

- 4K Mirror Stainless Steel:

- Characteristics: 4K mirror finish provides a moderate level of reflectivity and smoothness. It is the first level of mirror finish, where initial polishing removes most of the surface imperfections.

- Applications: Commonly used in kitchen appliances, basic decorative elements, automotive interiors, and furniture. This grade strikes a balance between cost and aesthetic appeal.

- 6K Mirror Stainless Steel:

- Characteristics: 6K mirror finish exhibits enhanced gloss and smoother surface compared to 4K. The additional polishing stages improve reflectivity significantly.

- Applications: Frequently used in mid-range kitchen appliances, retail displays, and certain architectural elements. It is suitable for applications where moderate aesthetics are critical.

- 8K Mirror Stainless Steel:

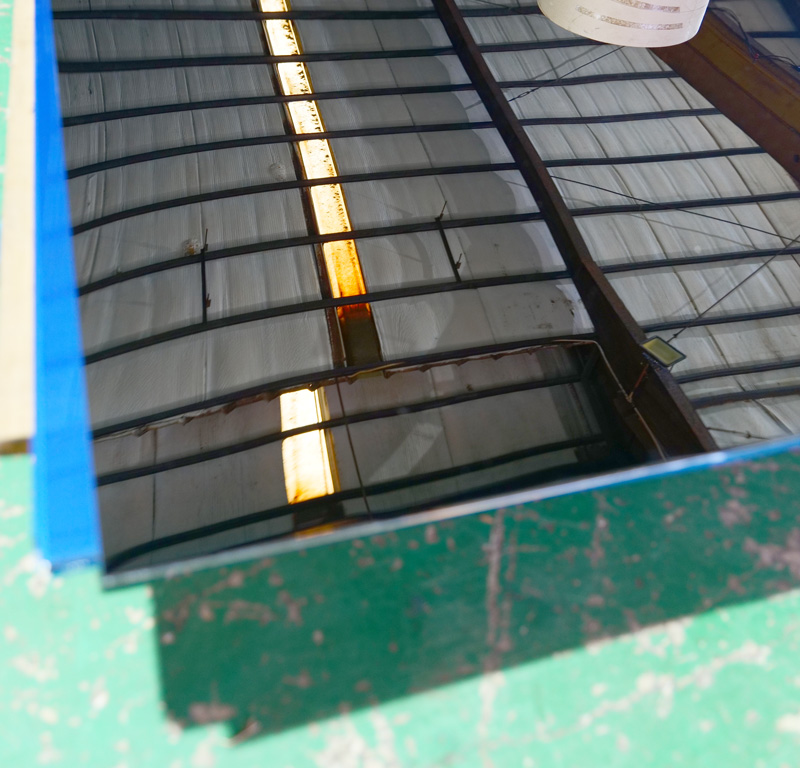

- Characteristics: 8K mirror finish is a highly reflective surface that provides a mirror-like quality. This grade requires meticulous polishing to achieve the desired shine and smoothness.

- Applications: Ideal for high-end consumer products, luxury automotive trim, and architectural projects requiring a sophisticated look, such as high-rise buildings and upscale interiors.

- 12K Mirror Stainless Steel:

- Characteristics: 12K mirror finish is the finest grade available, offering an exceptional level of reflectivity that approaches optical clarity. The manufacturing process for this grade is intricate, ensuring a flawless surface.

Applications of Mirror Stainless Steel

Mirror stainless steel finds applications across several industries, primarily due to its combination of beauty and functionality. Here are some notable sectors where various grades of mirror stainless steel are utilized:

1. Architectural and Interior Design

Mirror stainless steel plays a crucial role in architecture, where it is often used for decorative facades, wall panels, and elevator doors. Higher grades such as 8K and 12K are favored for their ability to enhance the visual appeal of buildings and interiors, creating striking reflections and a sense of spaciousness.

2. Automotive Industry

In the automotive sector, mirror stainless steel is a popular choice for trim, badges, and detailing. The 6K and 8K grades are commonly employed, as they provide the necessary aesthetic qualities while maintaining durability against the elements. Luxury car manufacturers may opt for higher grades to exhibit the finest craftsmanship.

3. Consumer Products

Mirror stainless steel is found in a variety of consumer products, such as kitchen appliances, bathroom fixtures, and décor items. The 4K and 6K finishes are often sufficient for these applications, offering a satisfactory level of shine without significant cost implications.

4. Industrial Applications

In industrial settings, mirror stainless steel is used in environments where hygiene is paramount, such as food processing and cleanroom applications. The smooth surfaces of grades 4K and 6K aid in maintaining cleanliness, as bacteria and contaminants are less likely to adhere to them.

Challenges in Producing High-Grade Mirror Stainless Steel

The production of high-grade mirror stainless steel poses several challenges:

1. Manufacturing Complexity

As the grade increases, the complexity of the manufacturing process also escalates. Creating a high-quality mirror finish requires multiple polishing stages, each demanding precision and care. The equipment used in this process must be advanced and well-maintained to achieve the desired results.

2. Cost Implications

Higher grades of mirror stainless steel come at a premium due to the intricate processes involved in their production. Manufacturers must balance quality and cost to remain competitive while delivering products that meet customer expectations.

3. Quality Assurance

Ensuring that the final product meets industry standards is crucial. Quality assurance processes must be robust, involving detailed inspections and testing to verify that the mirror finish is flawless and meets the required specifications.

4. Corrosion Considerations

Although stainless steel is inherently resistant to corrosion, the mirror finishing process can expose the material to elements that may affect its durability. Manufacturers must mitigate these risks, especially for higher-grade finishes used in harsher environments.

Conclusion

Understanding the different types of mirror stainless steel is vital for industry professionals looking to make informed decisions regarding material selection. From 4K, 6K, and 8K to the high-end 12K finishes, each grade offers unique properties and applications suited to specific needs. While the complexities involved in producing higher grades present challenges, the result is a stunning material that enhances both aesthetic and functional qualities across a myriad of applications. By recognizing the significance of these mirror finishes and their respective uses, businesses can capitalize on the benefits of mirror stainless steel in a competitive marketplace.